-

Ultima Visita

Più di un mese fa

Aggiornamenti di stato pubblicati da ygengineering

-

Top 5 Medical-Surgical Glove Brand Ranking

In professional environments such as hospitals and laboratories, wearing medical gloves can protect your hands from infections such as bacteria, medicine, and disease. Among them, rubber and latex gloves have better acid and alkali resistance and can be used for surgery and direct contact treatment. Since the use scenes of medical gloves are very professional, they are generally not accessible to many people, so there is no answer to the question of which medical gloves are good.

The recent new crown virus epidemic has caused many people to pay attention to the anti-virus protection of their hands. It can be foreseen that medical gloves will soon enter the C-end consumer market. Based on the data of medical gloves market research and comprehensively based on the product's fabric material, functional use, applicable scenarios, price and sales volume, brand awareness, user reputation evaluation and other strength data as a reference, we selected the following five major medical latex gloves brands for them Recommendations for consumers to make reference when making purchases.

Medis/Medispa

Medispo is the world's leading brand of medical gloves. It is produced by Guilin Hengbao Health Protection Co., Ltd. It has been a brand for more than ten years and is sold in more than 50 countries and regions around the world. Since its inception, Medipo has been committed to the innovation of applied technology in the medical surgical glove industry.

Ammex/Ammex

Ammex is a US-funded multinational company founded in 1988. It is a world-class supplier of health and safety and protective products. In the United States, Canada, Europe, the Middle East, Australia and Asia, Ammex has more than 20,000 Direct importers and service providers of users. As a manufacturer of disposable gloves and protective products, Amas continues to meet the requirements of users all over the world.

Gobon

Gobon is produced by Guilin Zizhu Latex Products Co., Ltd. The company was founded in 1966. It is the designated condom manufacturer of the National Population and Family Planning Commission and the chairman unit of the China Latex Industry Association. The company has an annual output of 970 million high-quality condoms and 72 million pairs of high-quality surgical gloves; it can produce high-quality examination gloves, household gloves and other latex products, with an annual production and sales of more than 220 million yuan and a profit and tax of more than 10 million yuan. The production and sales of condoms and medical gloves are among the best in the industry.

Henan Yugong Medical Equipment Co., Ltd. specializes in the production of gloves for the medical industry. The main products are: disposable sterile rubber surgical gloves, disposable medical rubber examination gloves (sterile, non-sterile), disposable films ( PE) Sanitary gloves, etc.

Intco

INTCO is produced by INTCO Medical Technology Co., Ltd. The company was established in 2009 in Zibo City, Shandong Province. It is a high-tech manufacturing enterprise dedicated to the research and development, production and marketing of medical equipment consumables. Its business covers medical protection, rehabilitation equipment, health care physiotherapy, inspection consumables and other products. Click here to know more about nitrile gloves making machine.

-

Working principle of drilling pump

If the entire drilling construction process is compared to human life activities, then the drilling pump, like the human heart, is the source of continuous circulation of drilling fluid from the ground to the bottom of the well, and then back to the ground from the bottom of the well. The drilling pump sucks the drilling fluid in the circulating tank, and at a pressure of 10-30 MPa and a delivery displacement of 20-60 liters per second, it passes through the ground high-pressure manifold, hose, drill pipe, and drill nozzle to the bottom of the well. , It will also form a high-pressure jet when flowing through the nozzle of the drill bit. Play the role of breaking rocks, cleaning the bottom of the well, and cooling the drill bit. When drilling with bottom hole screws or turbodrills, drilling fluid is the power source for power drilling tools. If the drilling pump fails to work normally and the drilling fluid cannot maintain circulation during the drilling process, downhole drilling engineering accidents will occur. It's as if the human heart stopped beating. Click here to know more details.

Drilling pump classification

A reciprocating pump is a kind of drilling pump commonly used in oil drilling rigs, and its function principle is exactly the same as that of general reciprocating pumps. The power end of the drilling pump is a set of crank and slider mechanisms. Because the liquid transported is mostly mud, it is also called a mud pump. There are many types of drilling pumps, which can be divided into double-cylinder pumps and triple-cylinder pumps according to the number of hydraulic cylinders of the pump. According to the number of times the piston sucks or discharges liquid once, it can be divided into single-acting pumps and double-acting pumps. At present, the most widely used oil drilling rigs at home and abroad are double-cylinder double-acting and triple-cylinder single-acting piston drilling pumps.

Work efficiency

The efficiency of the drilling pump directly affects the speed and progress of drilling. The pump valve, piston, cylinder liner and seal of the YG mud pump are the weakest parts of the drilling pump because they have been working in the drilling fluid containing fine sand for a long time, and the working environment and conditions are harsh. In recent years, with the joint efforts of scientific research and manufacturing units, my country has developed a number of high-quality, long-life drilling pump accessories, which greatly improves the working efficiency of drilling pumps.

In the 1980s, due to the rise and development of jet drilling technology, the matching update speed of high-horsepower drilling pumps was greatly accelerated. In just over ten years, the mud pump has developed from 600 horsepower in the past to 800, 1000 and 1300 horsepower now. Individual deep well drilling teams are also equipped with 1,600-horsepower drilling pumps.

-

The Basic Classification of Water Well Drilling Rigs

The essence of drilling is to try to solve the problems of breaking rock and removing cuttings, protecting well wall and deepening drilling. The water well drilling rig must complete water well drilling, well casing, well flushing and other operations. Through long-term production practice and scientific research, the drilling method can be divided into two drilling methods with industrial practical value: impact method and rotation method. Various well drilling rig models have evolved from these two methods.

According to drilling methods, water well drilling rigs are divided into three categories: impact drilling rigs, rotary drilling rigs and compound drilling rigs. According to the circulation method, it can be divided into four categories: mud positive circulation drilling rigs, mud reverse circulation drilling rigs, conventional air drilling rigs and air reverse circulation drilling rigs. According to the classification of drilling depth, it can be divided into three types: shallow well drilling rig, medium-deep well-drilling rig and deep well drilling rig. According to the type of assembly, it can be divided into three types: vehicle-mounted water well drilling rig, trailer mounted water well drilling rig and bulk water well drilling rig.

Understanding the common types and characteristics of water well drilling rig is only the first step to give full play to the use-value of the equipment. In order to make better use of the equipment and improve the drilling quality and operation efficiency of water wells, it is also necessary to do a good job in the design, selection, matching and use of drilling rigs. YG machinery will continue to organize and share relevant wonderful information for you.

-

Wedding, Banquet Foil Balloon Making Machine

To create a romantic, happy atmosphere, balloons are usually used for decoration. For example, balloons are used for decoration at weddings, birthday parties, business banquets and other high-end places. According to the material of producing balloons, there are mainly aluminum foil balloons and latex balloons. Can you tell the difference between the two types of balloons? Do you know how aluminum foil balloons are made?

Foil Balloons

Aluminum foil balloons are also called aluminum film balloons, which are made of aluminum film materials. Since the balloons are printed, they come in a variety of patterns and colors. The aluminum film balloon has an air nozzle that can be inflated, and it lasts for a long time after inflation. The aluminum foil balloon itself will not be damaged without external force.

latex balloon

Latex balloons are made of 100% natural rubber, no other artificial rubber is added, so latex balloons can be naturally decomposed. In terms of color, latex balloons have four categories: standard color, pearlescent color, crystal color, and fluorescent color. Shapes include circle, heart, plum blossom, magic strip, etc.

How to Make Foil Balloons?

Latex balloons and foil balloons are made using different balloon making machines. Here's how to make an aluminum foil balloon. Aluminum foil balloons are generally available with printed patterns and without patterns. The aluminum foil raw material is prevented from being placed on the reel, and it is made by cutting the aluminum foil balloon making machine, filling the air nozzle, and printing the pattern. From the raw material to the final product, it is automatically completed by the aluminum foil balloon making machine. Using the automatic aluminum foil balloon making machine to make aluminum foil balloons has high production efficiency and regular production shapes.

Yugong construction machinery equipment manufacturers also provide construction-specific machinery, such as Scrap Metal Shear For Excavator, paper rewinding machine, gunite machine for sale, slope hydroseeding machine, automatic sandblasting machine, ect.

-

Why need disinfection channel?

In our daily life, we go to all kinds of places and face all kinds of doors. In addition to the automatic doors in some operation stores, we need to touch many doors every day and open them by pulling or pushing. The door handle becomes an object that all people need to contact in and out, and all kinds of people have a cross contact process through the door. In densely populated areas, if one of the people who uses the door has bacteria, the door can make many people increase the possibility of disease.

In the period of epidemic of some infectious diseases, we have to take measures to disinfect the door handle and wash hands repeatedly when going out. These measures or need to increase the work intensity of cleaning personnel or personal awareness of safety and health, are not very convenient, there is a waste of time, not a perfect solution.

Advantages of intelligent atomization disinfection door products

1. Food level disinfection, safe and effective, non-contact disinfection.

2. Matrix full body disinfection without dead angle.

3. Humanized design and reasonable layout will not cause discomfort of respiratory tract and other organs.

4. The whole stainless steel material is corrosion-resistant and deformation resistant, light and movable.

5. Multi disinfection of plasma, ultraviolet and light wave, more thorough disinfection.

6. 220V city power, convenient switch, simple operation, economic and environmental protection.

7. Human body temperature alarm and thermal imaging temperature detector can be added to detect human body temperature.

What is the ozone disinfection cabin?

Ozone is a broad-spectrum and efficient bactericide. In foreign countries, it was first used for water consumption. Ozone disinfection is not only effective and reliable. And it does not produce halogenated organic compounds with carcinogenic effect. With the development of disinfection technology, the application range of ozone decontamination is also increasingly wide, which has attracted more and more attention. The ozone molecule consists of three oxygen atoms. That is O3. About 95% of ozone in the atmosphere comes from the photochemical reaction between the sun and plant volatiles, as well as the ionization between lightning and air. This YG product uses static electricity to simulate lightning to produce ozone.

-

Paper tube making machine for film,food,toilet paper

Toilet paper core making equipment is a machine and equipment for producing paper tubes. The produced paper tubes are used in various industries, such as tubes for chemical fiber industry, tubes for film industry, tubes for printing industry, tubes for paper industry, and tubes for leather industry. Tubes, food packaging tubes, construction industry tubes, exhibition industry tubes, etc. There are also various types of paper tube machines. The most common paper tube machine is the spiral paper tube machine and the flat roll paper tube machine.

1. Suitable for high-strength paper tubes such as aluminum foil, steel strip, copper foil, construction industry, etc.

2. The electrical appliance adopts the Japanese Mitsubishi brand.

3. There is a single-knife hydraulic knife/electric saw.

4. The main machine of the paper tube machine has a swing function, which does not need to move the glue rack and the paper rack. The operation is simple and convenient, saving labor and space, and with frequency conversion to save electricity.

5. High processing precision, using thick materials and precise electrical appliances.

YG supplies a wide variety of paper product processing equipment. For example, toilet paper making machine, paper bag machine, paper cup manufacturing machine, baby adult diaper making machine, sanitary pads making machine,wet wipe machine, paper rewinding machine for sale and other equipment.

-

With the introduction of plastic restriction orders and plastic ban orders in various countries, the market of the paper products industry has further expanded. The use of paper instead of plastic has been reflected in many industry scenarios such as catering, takeaway, and express delivery.

Overview of Paper Products

From the perspective of the industrial chain, the upstream of the paper product industry includes the paper processing industry, for example, the processing industry of various paper products such as paper, cardboard, handmade paper, and processed paper.

The downstream industry of paper products is mainly the processing industry of various paper products. For example, toilet paper processing industry, copy paper processing industry, catering paper product processing, signage and other paper product processing industries.

Development Status of Paper Products Industry

In recent years, my country's paper product packaging industry has maintained a steady development trend. The number of companies entering the paper product processing industry has continued to grow, and the industry's revenue scale and profit have maintained steady growth. According to statistics, in 2020, the enterprises above designated size in my country's paper product packaging industry realized the main business income of 288.474 billion yuan, a year-on-year decrease of 0.43%; A year-on-year increase of 23.05%.

In recent years, my country's export of paper products and paper product processing equipment to foreign countries is also increasing. As the global packaging industry gradually shifts to developing countries and regions represented by China, the export status of my country's paper product packaging industry has become increasingly prominent. In 2020, the total import and export volume of my country's paper packaging industry was 6.76 billion US dollars, of which the export value was 6.613 billion US dollars, a year-on-year increase of 4.08%.

The future development trend of paper products industry

Green environmental protection and economic development are the common goals pursued by all countries. Green environmental protection is to achieve green environmental protection from design, production, packaging and other links. In the future, the paper product development industry will surely develop towards recyclability, reuse, degradability, de-plasticization and replacement of plastic.

Production intelligence, automation

With the improvement of scientific and technological water bottles, the production of the packaging industry will gradually develop towards automation and intelligence in the future. Intelligent production, integrated printing and packaging, digital manufacturing, etc. not only greatly improve production efficiency, release labor, and reduce labor costs. And it will also create greater economic benefits.

Production service capability upgrade

With the rapid economic and social development, the stickiness of upstream and downstream industries will be further strengthened. The paper products produced by the production industry provide diversified demands for the processing and manufacturing of downstream industries. Paper product manufacturers will also be upgraded to become comprehensive service providers, and the requirements for comprehensive service will be gradually upgraded.

Paper product processing equipment

Paper product processing equipment occupies an important position in the development of the paper product industry. It is the most important equipment to realize the rapid processing of paper products and create economic benefits. The upstream paper product industry includes paper machines, which create various types of base paper and provide raw materials downstream. There are many downstream paper products processing equipment, such as tissue paper making machine, paper core making machine,paper bowl machine, paper cup machine,paper bag machine,diaper manufacturing machine,plastic lid forming machine, paper rewinding machine,rectangular paper bowl making machine, punching machine, slitting machine, copy paper processing equipment and other processing machines.

-

What is wet sandblasting?

Wet blasting is a technique for surface preparation using water, abrasives and compressed air.

"Wet blasting" refers to a technology that uses the power of compressed air to spray a mixture of water and abrasives at high speed to achieve surface cleaning, processing and modification of metals, plastics, ceramics and other materials. Since it is wet processing, it is also suitable for fine processing using abrasives as small as several microns.

Advantages of wet blasting

Wide selection of abrasive grain sizes, shapes and materials

Because the abrasive particles are carried by water to the target, finer particles can be used compared to dry blasting.High fluid control and controllability

The grinding fluid mixed with water and abrasive grains can realize fluid control, so the processing precision is higher.Less abrasive residue

After machining, the abrasive particles are washed away by water, so less particles remain on the machined surface.Capable of handling ultra-thin targets

The processing pressure is small, and the ultra-thin target will not be damaged during processing.Adding chemicals can get the effect of secondary treatment

Chemicals can be dissolved in water, and chemical treatment can be performed at the same time as sandblasting.The principle of wet sandblasting

Wet sandblasting is an easy-to-automate and environmentally friendly way to circulate the grinding fluid.

The basic principle of wet sandblasting is as follows. The grinding liquid (mixture of water and abrasive) in the grinding liquid tank is drawn to the sandblasting gun by a pump, and is sprayed onto the target material by the action of compressed air in the sandblasting gun. The grinding fluid is recovered to the grinding fluid tank for recycling. Click here to know more wet blasting machine details. -

The excavator can not only be used to excavate the soil but also can be replaced with other excavator attachments to realize various functions such as handling, splitting, and shearing. According to statistics, there are currently more than 20 kinds of excavator attachments. YG Excavator Attachment Manufacturer introduces the following 7 commonly used excavator attachments.

1. Excavator accessories — -breaker hammer

Breaking hammer, also known as hydraulic breaker hammer, is also called gun head in the south, and it is mainly used for mining ore in mines and demolition of concrete.

2. Excavator accessories — -hydraulic shears

Hydraulic shears, also known as hydraulic pliers, are mainly used in the demolition of buildings, and their efficiency is much higher than that of breaking hammers.

3. Excavator accessories — -vibration rammer

Vibratory rammers, also known as hydraulic rammers or compactors, are mainly used for water conservancy slope protection and the construction of high-speed and railway slopes. Some small excavators are equipped with rammers to compact building foundations.

4. Excavator attachment — -Quick connector

Quick coupler, also known as quick coupler or quick changeover joint, is specially used to switch breakers (or other equipment) and buckets. Generally, a skilled operator can switch equipment in less than 30 seconds, but in the past, it took 40 to 60 minutes, and more than two people needed to operate.

5. Excavator accessories — -ripper

The ripper is also known as the ripper. It is mainly used for weathered stone construction. It is easier to use layers in working conditions. It is laborious to dig with a bucket, and it is a bit easy and wasteful to use a breaker. At this time, using a ripper will greatly improve the construction efficiency. First use a ripper to separate the soil layer or weathered stone layer, and then use a quick coupler to switch the bucket for loading.

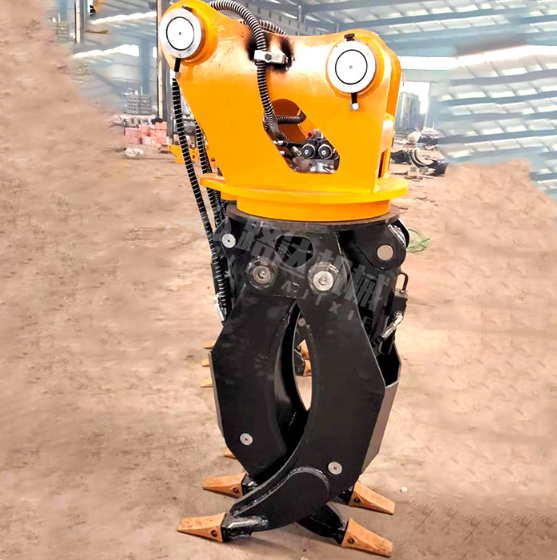

6. Excavator attachment — — wood grabber

Wood grabs, also known as wood clamps, are divided into hydraulic wood grabs and mechanical wood grabs, and hydraulic wood grabs are divided into hydraulic rotary wood grabs and fixed wood grabs. The excavator wood grabber can be used to grab stones and scrap steel after redesigning and modifying the claws. It is mainly used to grab wood and bamboo. The loading and unloading is very fast and convenient.

7. Excavator accessories — -hydraulic rock drill

The hydraulic rock drill, also known as the drilling machine, is mainly used for blasthole construction in mines.

In addition to the above several front-end replacement devices, there are many other types. Such as vibratory pile driver, Car Dismantling Shear,Scrap Metal Shear For Excavator, etc. It seems that in addition to playing with the bucket, the excavator should be proficient in all eighteen martial arts and develop in an all-around way!

-

What is the plastic film?

Technically speaking, plastic film is any plastic with a thickness of less than 10mm, and it is usually made of polyethylene (PE) resin, such as common zipper bags, food bags, bubble wrap, agricultural plastic films, etc. At present, the global demand for plastic film continues to rise. Plastic products are difficult to decompose, and if they are not recycled, the harm to the environment is huge. Therefore, the recycling of plastic films is of great significance. So how to recycle plastic film?

Significance of waste plastic film recycling:

In recent years, with the large-scale promotion of plastic film mulching, especially the full-film double-furrow sowing technology, the use of agricultural film has increased year by year, and the problem of “white pollution” has become increasingly prominent. The main component of waste agricultural plastic film is polyvinyl chloride or polyethylene, which is difficult to degrade under natural conditions and has a residual period of more than 20 years. If it is not cleaned and recycled in time, the amount of residual film in the soil will accumulate year by year. After the agricultural film fragments enter the soil, they will change the physical properties of the soil, reduce the air permeability of the soil, seriously affect the growth of the root system of the crops, and lead to the reduction of crop production.

How to recycle plastic film?

To recycle plastic film, we don’t simply put it in the trash, but take it to the designated place. In these PP PE film recycling plants, the plastic film is cleaned, recycled, and granulated through processes such as plastic film cleaning, drying, and granulation. Plastic film particles that have been cleaned and granulated can be recycled again and reused through processes such as film blowing, bag making, and injection molding. Related recommendations: PP PE film washing line is a device for cleaning and recycling plastic films.

Related Machine:

What happens when the plastic film is recycled?

During the recycling process, the plastic film comes into the factory in bales, which are then disassembled by hand or by a cutter, and then sent to a shredder to cut into pieces. The film is then washed and inspected for contamination, cleaned, and dried before being recycled. The film goes into an extruder, where heat and pressure melt the plastic. Molten plastic is extruded from an extruder to form thin strands, cooled, and cut into pellets, which are used by manufacturers to produce new plastic film products, plastic containers, crates, pipes, new plastic bags and pallets, and more.

Plastic Film Recycling Challenges

Plastic film recycling programs can only be successful if recyclers accumulate large amounts of material to recycle, which is one reason why plastic film can only be collected at designated locations rather than curbside recycling bins. Large retail stores collect plastic film from consumers and add it to film produced in their own factories.

However, the challenge here is that recycling companies are often not equipped to recycle the plastic film, so the plastic film collected is often not recycled smoothly, and it ends up in a landfill. As far as the United States is concerned, only 5% of the plastic film processing capacity, most of the recycled plastic film comes from retail store pallet packaging because they are cleaner. In addition, the plastic film recycling market is not ideal because it is more profitable to make a new plastic film than to recycle old plastic film, knowing that the cost of collecting, sorting, cleaning, and reprocessing old plastic film is often 100 times that of making a new plastic film, That’s a scary number, and it will take social resources to encourage recycling companies to take action.

Some frequently asked questions

A. Is recycled plastic film sustainable?

Recycling plastic film is more sustainable than throwing it away, but the plastic film itself is never sustainable as it can only be ‘downcycled’ — made into something of lower quality and dependent on the continuation of virgin plastic Production. The cost of recycling plastic film is also 100 times the cost of making a new film.

B. Is something like plastic wrap compostable?

New and innovative plastic films include iterations made from cornstarch and potato waste. These plant-based alternatives decompose into compost piles within six months.

C. How long does it take for an ordinary plastic film to decompose?

Generally speaking, plastic products take 20 to 1000 years to decompose. Because the plastic film is so thin and flexible, its decomposition should be at the low end of the above range.

-

Fog cannon machine, also known as mist cannon machine and water mist cannon spraying machine, is a device specially developed for dust suppression. Now the equipment can be used to print dust in the environment or in places with large dust such as mines, docks, and stone quarries. The sprayed water mist can well condense with the dust, and the dust falls under the action of gravity, and the dust removal and dust suppression effect is remarkable.

Why do you need a fog cannon?

Long-term exposure to dust will cause harm to the human body. Dust may poison the human body, damage the cornea, cause pneumoconiosis, and affect skin health. The water mist sprayed by the fog cannon is the best device to suppress the split. Therefore, many factories, docks, transfer stations, mines, coal yards, etc. that generate a lot of dust will use this equipment for dust suppression.

Fog Cannon Model:

Fog cannon fan material: Q235. Q345 steel plate or 304 stainless steel material,

The thickness of the air duct steel plate is greater than 3mm

Fog cannon electrical control box: carbon steel control box or 304 stainless steel control box, with double door structure, the thickness of the control box is not less than 2mm

Explosion-proof fog cannon electrical control box:

(1) Carbon steel explosion-proof control box

(2) 304 stainless steel explosion-proof control box (overall thickness 4mm, flange thickness 12mm)

Protective function:

(1) Phase sequence protection, the fans, and pumps will not start when the phase sequence is reversed

(2) Overcurrent protection, when the current of the device is too large, the device will automatically stop running

(1) Low water pressure protection, when the water pressure is too low, the equipment will automatically stop running to protect the water pump

(2) Automatic drainage, when the equipment is shut down, the water in the pipeline is automatically drained

Heating: use self-limiting heat tracing cables to prevent ice from freezing on the spray ring and the water pump to meet the requirements of winter use

Nozzle selection: copper nozzle, high quality 304 stainless steel nozzle

Conditions for suppressing dust

Dust suppression requires two conditions:

1. There are enough dust particles and water droplets of the same size.

2. Dust particles and water droplets are in a closed area so that the agglomeration can fully occur and continue.

The high-pressure spray fan produced by Zhengtong can generate ultra-fine mist droplets through the strong wind formed by system pressurization and turbocharging. The weather can spray dust, decompose and desalinate the particle concentration in the air, and can effectively decompose the polluting particles and dust in the air, and effectively relieve the haze. According to reports, the purchase of such a big guy costs 50,000 to 150,000 yuan. The pollutant particles floating in the air are quickly forced to the ground to achieve the effect of cleaning the dust-reducing air.

Advantages compared to ordinary sprinklers:

The fog cannon can be directly installed at the rear of the sprinkler and can be atomized into beads equivalent to the dust by pressure. The energy is completely suppressed, and at the same time, the amount can be adjusted according to actual needs. Compared with the ordinary sprinkler, it can save 50%, and the resource rate is improved. The ordinary sprinkler only sprays along the nozzle to suppress the road dust, and cannot effectively and quickly solve the dust in the air.

Related machines

YG machine manufacturer also supplies the environmental machine (fog cannon machine, slope hydroseeding machine), sanitary equipment(paper rewinding machine, toilet paper making machine, nonwoven bag making machine), construction machine(Diamond Wire Saw Machine, concrete wall saw, rock splitter machine), wire mesh welding machine and other machines.