-

Ultima Visita

Più di un mese fa

Contenuti pubblicati da ygengineering

-

The excavator can not only be used to excavate the soil but also can be replaced with other excavator attachments to realize various functions such as handling, splitting, and shearing. According to statistics, there are currently more than 20 kinds of excavator attachments. YG Excavator Attachment Manufacturer introduces the following 7 commonly used excavator attachments.

1. Excavator accessories — -breaker hammer

Breaking hammer, also known as hydraulic breaker hammer, is also called gun head in the south, and it is mainly used for mining ore in mines and demolition of concrete.

2. Excavator accessories — -hydraulic shears

Hydraulic shears, also known as hydraulic pliers, are mainly used in the demolition of buildings, and their efficiency is much higher than that of breaking hammers.

3. Excavator accessories — -vibration rammer

Vibratory rammers, also known as hydraulic rammers or compactors, are mainly used for water conservancy slope protection and the construction of high-speed and railway slopes. Some small excavators are equipped with rammers to compact building foundations.

4. Excavator attachment — -Quick connector

Quick coupler, also known as quick coupler or quick changeover joint, is specially used to switch breakers (or other equipment) and buckets. Generally, a skilled operator can switch equipment in less than 30 seconds, but in the past, it took 40 to 60 minutes, and more than two people needed to operate.

5. Excavator accessories — -ripper

The ripper is also known as the ripper. It is mainly used for weathered stone construction. It is easier to use layers in working conditions. It is laborious to dig with a bucket, and it is a bit easy and wasteful to use a breaker. At this time, using a ripper will greatly improve the construction efficiency. First use a ripper to separate the soil layer or weathered stone layer, and then use a quick coupler to switch the bucket for loading.

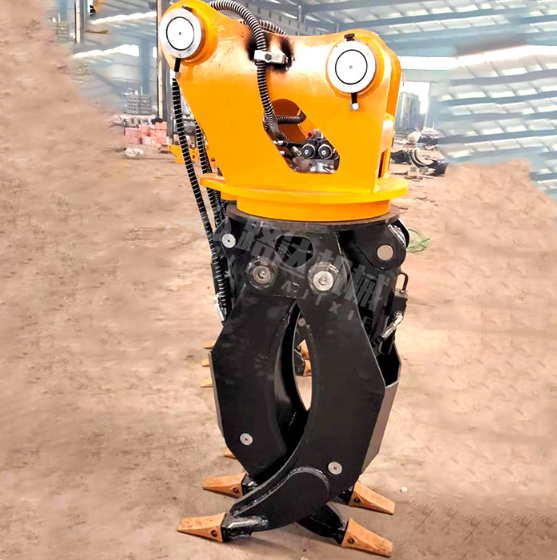

6. Excavator attachment — — wood grabber

Wood grabs, also known as wood clamps, are divided into hydraulic wood grabs and mechanical wood grabs, and hydraulic wood grabs are divided into hydraulic rotary wood grabs and fixed wood grabs. The excavator wood grabber can be used to grab stones and scrap steel after redesigning and modifying the claws. It is mainly used to grab wood and bamboo. The loading and unloading is very fast and convenient.

7. Excavator accessories — -hydraulic rock drill

The hydraulic rock drill, also known as the drilling machine, is mainly used for blasthole construction in mines.

In addition to the above several front-end replacement devices, there are many other types. Such as vibratory pile driver, Car Dismantling Shear,Scrap Metal Shear For Excavator, etc. It seems that in addition to playing with the bucket, the excavator should be proficient in all eighteen martial arts and develop in an all-around way!

-

The emergence of small excavators has brought great convenience to the majority of construction workers, and it can help builders complete construction work more easily and efficiently. Small excavators are welcomed by customers for their small size and wide range of applications. The operation of the small excavator is very simple and can effectively replace manual work, greatly saving manpower and reducing the cost of manpower investment.

What types of mini excavators are there?

There are five classification methods for the classification of common small excavators, namely, according to the form of the traveling device, according to the transmission mode, according to the form of the working device, according to the driving mode and according to the purpose.

① It has a small caterpillar excavator and wheel type. The crawler excavator has a larger chassis and is suitable for complex road conditions. Therefore, its application is very extensive. The tire-type small excavator has fast walking speed and good maneuverability.

② Classification by transmission mode: There are two types: mechanical and hydraulic. Mechanical single-bucket small excavators rely on mechanical transmission and require various gearboxes, winches, wire ropes, hooks, pulleys and other parts. The structure is complex, and it has gradually been eliminated in small and medium-sized single-bucket small excavators. The hydraulic single-bucket small excavator eliminates many complicated mechanical intermediate transmission parts, simplifies the structure, improves the transmission performance, works smoothly, operates flexibly, and has high productivity.

③Classified by the form of working equipment: there are backhoe, front shovel, grab shovel, dragline and other forms. When backhoeing, the digging direction faces the fuselage, and it is used to dig the soil below the parking surface. It is flexible in work and widely used. It is the main working device form in hydraulic small excavators.

④ There are internal combustion engine-driven and electric-driven small excavators according to drive mode.

⑤According to the purpose, there are general excavators, mining excavators, marine excavators, and other special excavators.

Application of mini excavator:

1. For orchards: digging fertilization ditches, planting trees, weeding, cultivating soil, opening up wasteland, etc.;

2. Trench digging: digging cable trenches, water or sewage pipelines, natural gas pipelines, etc.;

3. Landscaping: planting trees, digging ditches, etc.;

4. Mountain contracting: planting trees, repairing terraces, digging ditches, opening paths, weeding and opening up wasteland, etc.;

5. Indoor aspects: indoor demolition, basement backfill;

6. In terms of crushing: road and ground concrete crushing, mountain stone crushing, etc.;

7. Mine aspects: tunnel and cave construction, mines and shafts, etc.;

8. Vegetable greenhouses: for deep digging;

9. In terms of digging medicinal materials: for digging yams, etc.;

In addition, agricultural and forestry planting, farmland reconstruction, small earthwork engineering, municipal engineering, road surface repair, farms, garden cultivation, and river and ditch dredging projects, and other operating environments.

Features of the mini excavator:

In this era of mechanization, most users gradually use mechanized production to replace manpower. The small excavator has reliable quality and stable performance, and can adapt to harsh construction environments. The equipment is matched with a high-horsepower engine and has high construction efficiency. The structure of the equipment is simple, the operation is simple and convenient, and the maintenance cost is low. It can be matched with different excavator attachments to realize various functions such as rotary excavation, crushing, hook cleaning, bulldozing, etc., realizing one machine with multiple functions. The small excavator is suitable for various soil properties, has good use effect, simple operation, small and flexible, convenient transportation, and can work in small places.

-

What is the plastic film?

Technically speaking, plastic film is any plastic with a thickness of less than 10mm, and it is usually made of polyethylene (PE) resin, such as common zipper bags, food bags, bubble wrap, agricultural plastic films, etc. At present, the global demand for plastic film continues to rise. Plastic products are difficult to decompose, and if they are not recycled, the harm to the environment is huge. Therefore, the recycling of plastic films is of great significance. So how to recycle plastic film?

Significance of waste plastic film recycling:

In recent years, with the large-scale promotion of plastic film mulching, especially the full-film double-furrow sowing technology, the use of agricultural film has increased year by year, and the problem of “white pollution” has become increasingly prominent. The main component of waste agricultural plastic film is polyvinyl chloride or polyethylene, which is difficult to degrade under natural conditions and has a residual period of more than 20 years. If it is not cleaned and recycled in time, the amount of residual film in the soil will accumulate year by year. After the agricultural film fragments enter the soil, they will change the physical properties of the soil, reduce the air permeability of the soil, seriously affect the growth of the root system of the crops, and lead to the reduction of crop production.

How to recycle plastic film?

To recycle plastic film, we don’t simply put it in the trash, but take it to the designated place. In these PP PE film recycling plants, the plastic film is cleaned, recycled, and granulated through processes such as plastic film cleaning, drying, and granulation. Plastic film particles that have been cleaned and granulated can be recycled again and reused through processes such as film blowing, bag making, and injection molding. Related recommendations: PP PE film washing line is a device for cleaning and recycling plastic films.

Related Machine:

What happens when the plastic film is recycled?

During the recycling process, the plastic film comes into the factory in bales, which are then disassembled by hand or by a cutter, and then sent to a shredder to cut into pieces. The film is then washed and inspected for contamination, cleaned, and dried before being recycled. The film goes into an extruder, where heat and pressure melt the plastic. Molten plastic is extruded from an extruder to form thin strands, cooled, and cut into pellets, which are used by manufacturers to produce new plastic film products, plastic containers, crates, pipes, new plastic bags and pallets, and more.

Plastic Film Recycling Challenges

Plastic film recycling programs can only be successful if recyclers accumulate large amounts of material to recycle, which is one reason why plastic film can only be collected at designated locations rather than curbside recycling bins. Large retail stores collect plastic film from consumers and add it to film produced in their own factories.

However, the challenge here is that recycling companies are often not equipped to recycle the plastic film, so the plastic film collected is often not recycled smoothly, and it ends up in a landfill. As far as the United States is concerned, only 5% of the plastic film processing capacity, most of the recycled plastic film comes from retail store pallet packaging because they are cleaner. In addition, the plastic film recycling market is not ideal because it is more profitable to make a new plastic film than to recycle old plastic film, knowing that the cost of collecting, sorting, cleaning, and reprocessing old plastic film is often 100 times that of making a new plastic film, That’s a scary number, and it will take social resources to encourage recycling companies to take action.

Some frequently asked questions

A. Is recycled plastic film sustainable?

Recycling plastic film is more sustainable than throwing it away, but the plastic film itself is never sustainable as it can only be ‘downcycled’ — made into something of lower quality and dependent on the continuation of virgin plastic Production. The cost of recycling plastic film is also 100 times the cost of making a new film.

B. Is something like plastic wrap compostable?

New and innovative plastic films include iterations made from cornstarch and potato waste. These plant-based alternatives decompose into compost piles within six months.

C. How long does it take for an ordinary plastic film to decompose?

Generally speaking, plastic products take 20 to 1000 years to decompose. Because the plastic film is so thin and flexible, its decomposition should be at the low end of the above range.

-

The core drilling rig is a kind of drilling rig, which is mainly used as a construction machine for building foundation engineering holes. At present, core drilling rigs are widely used in infrastructure projects such as municipal construction, highway bridges, and high-rise buildings. The diamond core drilling rig is suitable for the soil geological conditions in most areas of our country, and has a wide range of applications. Basically, it can meet the needs of bridge construction, high-rise building foundation and other projects. At present, core drilling rigs have been widely studied and applied to various bored pile projects in enterprises. Therefore, it is very important to discuss the construction preparation of the core drilling rig and the commonly used clear water construction technology.

The use of core drilling rig

The core drilling rig is a kind of core drilling technology equipment, which can be mainly used for the general survey and exploration of metal and non-metal solid minerals. In addition, it can also be used in engineering geological survey, hydrogeological survey, oil and gas exploration, water well drilling, etc.

Core Drilling Rig Features

The core drilling rig system has the characteristics of large installed power, large output torque, high axial working pressure, flexible maneuvering time, high construction management efficiency, and multiple functions.

In addition, because core drilling rigs require relatively complete, non-mixed, non-flexible formation rock samples, core drilling rigs are all rotary drilling rigs. According to the structure of the gyrator of the drilling rig, the core drilling rig can be divided into three categories: vertical shaft type, rotary table type and mobile gyrator. The core drilling rig is composed of basic components such as slewing mechanism, feeding mechanism, lifting mechanism, transmission mechanism, control device and base. Depending on the type of drilling rig, some core drilling rigs may also be equipped with control and measuring instruments or other attachments.

Other rigs recommended

YG supplies many kinds of drilling rigs for sale, such as water well drilling machine (small water well drilling machine, portable water well drilling machine), DTH drilling rig, anchor drilling rig, HDD Machine, rotary drilling rig, and other drilling rigs.

-

Plastic toys are a common product in our daily life, so do you know how it is made? YG injection molding machine manufacturers tell you that most of them are made by injection molding. Other plastic products, plastic chairs, plastic basins, plastic baskets, plastic toys, car upholstery, earphones, etc. are also made by injection molding.

Why are children's toys made of plastic?

Plastic is a material with high polymer as the main component. Plastic softens when heated, hardens when cold, easy to form, easy to color, and wear-resistant. And the plastic toy is very light, and the baby will not have any pressure in the hand. Toys made of plastic are easier to disinfect and clean, and will not bring any hidden dangers to the baby. Another important reason is that plastics are easy to mold. Molten plastic is molded into various shapes of toys through various shapes of molds. This is why plastic toys are so colorful.

So what are the materials used to make plastic toys?

Plastic children's toys are a large category of toys, so what kind of plastic are plastic children's toys made of? There are many raw materials for plastic toys, such as ABS, PVC, PP, PC, PE, EVA, PU, etc.

ABS is the main material of the plug-in building blocks, and the three letters represent the three substances of "acrylonitrile, butadiene and styrene" respectively.

Most of the toys (except balls) that need to be inflated are made of PVC, such as croissants, vaulting horses, and balloons.

PP materials are mainly used in small toys such as gutta-percha and rattles. First, they can be imported, and second, they can be sterilized by boiling in high temperature water.

Soft PE is mainly used for film products, such as food cling film and plastic bags; its hard properties are suitable for one-time injection molding products and hollow products.

The most typical PE is to make rocking horses and slides, which need to be formed at one time, and at the same time, there are medium and large toys that are hollow in the middle.

There are basically three kinds of wheels for our common strollers, such as baby strollers, scooters, balance cars, and bicycles, foam, solid, and inflatable. In addition to the EVA on the foam wheel, there is also a PU.

How are toys made?

The production of toys is mainly made by plastic toy manufacturing machine. There are four stages in the production process, namely filling, holding pressure, cooling, and demoulding. Under the push of the screw, the plastic is injected into the closed cavity. During the advancing process, the plastic rubs against the cavity wall, and the heated plastic becomes molten. Under high pressure, molten plastic is injected into the mold cavity for molding. After cooling, forming and solidifying, it is the final product.

Other plastic products have roughly gone through the above steps, but only use different shapes of molds. Therefore, you can make different finished products by changing different molding dies. YG injection molding machine manufacturers provide molds for various products, such as plastic chair making machine,plastic chair molds, plastic toy mould, plastic pot molds, plastic tray molds, etc.

-

In our life, we come into contact with many finished products made of plastic, such as plastic chairs, plastic bags, plastic basins, plastic cylinders and other products. Many of these products are injection molded using plastic injection molding machines? What are these injection molding products? How does the injection molding machine process these products?

What is an injection molding machine

Injection molding machine, also known as injection molding machine or injection molding machine, is the primary molding equipment for making thermoplastic or thermosetting plastics into various shapes of plastic products using plastic molding molds. The emergence of injection molding machines has injected a fresh force into the plastics processing industry, making the plastics processing industry move towards automation. Injection molding machines can reduce manual labor, reduce costs, ensure safety, increase labor productivity, and improve product quality. There are various types of injection molding machines, such as vertical, horizontal, vertical-horizontal composite and so on. It can heat and shape plastic to make plastic basins, plastic bowls, plastic drinking cups, plastic stools, plastic toys and many other products.

What are the applications of injection molding machines?

The application of plastic chair making machine is very extensive, and it is used in many fields such as automobile industry, household appliances, industry, medical treatment, daily necessities and so on.

Automotive industry: such as lights, housings, steering wheels, bumpers, other interiors, etc.

Home appliances: refrigerators, washing machines, TV casings, rice cookers, sewage fans, etc.

Electronic products: earphones, charging cables, mobile phone cases, mice, keyboards, data cables.

Daily necessities: Disposable water cups, plastic chairs, plastic toys, sockets, etc.

School supplies: stationery boxes, folders, ballpoint pens, etc.

Medical supplies: plastic needles, infusion sets

Most of the products in our lives are produced using injection molding equipment. With the continuous progress and development of the times, the application of injection molding machines will become more and more extensive in the future.

The development prospect of injection molding machine

At present, the largest demand for injection molding machines is in the automotive manufacturing industry. In modern automobile manufacturing, many parts are made of plastic in order to reduce the weight of the car body. Most of the plastic casings, instrument panels, steering wheels, bumpers, lights, etc. are injection molded parts. The plastics used in the manufacture of automobiles are mostly engineering plastics, such as PP, PC, PPC, PBT, TPO, PPS, etc.

The second largest market for injection molding machine applications is the home appliance (environmental protection) market. Refrigerator, color TV, washing machine, water heater, solar cell, plastic tray, turnover box, etc. These products are oriented to the environment-friendly and energy-saving market, and there is a huge demand for injection molding products.

The third most in-demand market is the electronics, IT, medical and smart toy industries. In these fields, small and micro injection molding machines are the main products. In this field, many injection molding machines have entered the home, such as the production of many motors, electrical appliances, electronic components, converters, precision medical components and smart toy components.

The fourth area where injection molding machines are widely used is construction. Not only China, but many countries need to use injection-molded pipe fittings in many infrastructure construction, construction, irrigation, water saving, telecommunication, cable and other construction projects every year. Therefore, the market potential of these injection-molded pipe fittings is huge.

From the above analysis, we know that the injection molded parts produced by injection molding machines have a very wide range of applications in many fields. Moreover, injection molding machines have become an indispensable part of these fields and have very broad prospects.

YG also supplies plastic bag,plastic container,PE plastic products and other products processing machine.Such as side sealing bag making machine,plastic cup making machine,plastic egg tray making macine,plastic chair mold,ect.

-

Ditch forming machine is widely used in various canal related projects, it speeds up the construction progress and improves the quality of the canal. The canal forming machine is simple and durable, and is widely used in the lining construction of various channels such as farmland water conservancy, land improvement, highway ditch drainage, high-speed and high-speed railway ditch drainage, urban municipal drainage, aquaculture canals, etc. According to the different shapes of lining water channels, there are trapezoidal water channel forming machines, rectangular water channel forming machines, U-shaped water channel forming machines and special-shaped water channel forming machines.

How does a trench former work?

First start the electric vibrator to feed the concrete into the hopper of the trench forming machine. Start the hydraulic pump station, the oil cylinder starts to expand and contract, and the propeller pushes the concrete into the U-shaped cavity formed by the channel forming mold. At this time, the forming mold acts as an inner mold tire, and the formed concrete is adsorbed on the wall of the channel repaired by the mechanical blade, and the top of the channel is also extruded and formed at the same time.

At the same time, the vibration of the electric vibrator and the push of the hydraulic cylinder are used to generate extrusion and dense force, so that the guide rollers on both sides of the front of the machine body move linearly in the rails placed on both sides of the channel, so as to realize the function of automatic walking.

Why use a trench former?

Generally, the lining distance of the trench is relatively long, and the amount of engineering is large. If artificial light pouring is used, the construction process is relatively slow. Also, artificially lined drains can be uneven. Assuming that manual pouring is used, each person can pour a maximum of 20 meters per day, and the labor is too expensive and the construction period is too long. The contractor can't make much money and doesn't want to take it. However, if it is made by a cast-in-place molding machine with a canal, it is normally more than 500 meters a day, and only 1-2 people are required to operate the machine, saving labor and time. Therefore, more and more people are now using cast-in-place gutter forming machines.

Features:

Direct pour without the use of formwork

Concrete can be prepared on site and used on site.

Buckets of specific shapes can be customized to dig trenches according to construction needs.

Hydraulic propelling walking device, good molding effect.

The hopper is equipped with a screw feeding device to prevent the accumulation of concrete.

Equipped with customized generator, stable performance, low fuel consumption and low cost of use.

The lined ditch has good shape, smooth surface and simple maintenance.

The construction quality is stable and the water resistance is high.

Cast-in-place side water canal forming machine Channel forming machine has been widely welcomed by customers since its development and production. The products are exported to Xinjiang Urumqi, Gansu Lanzhou Baiyin, Ningxia Yinchuan, Qinghai Xining, Inner Mongolia Hohhot, Shaanxi Yan'an Xi'an, Shanxi Taiyuan Yulin, Jiangxi Ganzhou, Liaoning Shenyang, Anhui Hefei, Heilongjiang, Liaoning, Jilin and other regions,

Trench forming machines can pour hundreds of meters, or even kilometers at a time, all at once. It has made significant contributions to the construction of ditches for farmland irrigation, urban municipal drainage, and aquaculture drainage. The U-shaped channel forming machine equipment and T-shaped channel forming equipment produced by our factory are fully automatic one-time forming machines, without secondary lining, to ensure the quality of the removed section, the smoothness of the inner surface of the channel, and the anti-seepage ability. Therefore, the trench forming machine has been widely welcomed by customers since its production.

Other environmental protection equipment recommended

Yugong construction machinery and equipment manufacturers also provide other environmental protection equipment. For example, Fog Cannon Machine, dust suppression truck, Soil Spaying Machine

-

What is a plastic thermoforming Machine?

The plastic cup thermoforming machine, also known as the blister machine, is important molding equipment in food, medicine, industry, and other fields. It can heat and plasticize various plastics such as PVC, PP, PE, PET, HIPS, etc. The finished packaging is obtained by sucking various thermoplastic rolls into various shapes.

The main application of blister machine

The plastic cup-making machine is widely used in various packaging industries, such as the plastic packaging industry, food packaging industry, pharmaceutical industry, industry, manufacturing industry, etc.

1. Plastic packaging industry (blister packaging, plastic, batteries, toys, gifts, hardware, home appliances, electronics, stationery, decoration);

2. Food packaging industry (fast food boxes, fruit trays, biscuit boxes);

3. Pharmaceutical industry (pill packaging, tablet packaging);

4. Industrial cooling tower cooling water deflector, etc.;

5. Three-dimensional relief patterns for decoration, plastic ceilings, siding, automotive materials, sanitary equipment, and other manufacturing industries.

6. Suitable for the production of various color sheets: polyethylene PS, polyvinyl chloride PVC, plexiglass, ABS, polymethyl methacrylate; flocking sheets; environmental protection sheets APET, PET, PP, etc.; photodegradable materials; Plastic products such as biodegradable materials

The principle of plastic cup forming

The blister machine mainly uses the vacuum suction generated by the vacuum pump to blister the heated and softened thermoplastic plastic sheet into various shapes of containers through the mold. Thermoplastic materials are available in PVC, PET, PETG, APTT, PP, PE, and PS. After changing different molds, the equipment can make plastic sheets into vacuum covers, blister trays, blister shells, toy blister packaging, stationery blister packaging, and other products.

vacuum hoods, blister trays, blister shells, etc. At present, the common products on the market are: plastic packaging for daily necessities, plastic packaging for hardware, plastic packaging for automotive supplies, plastic packaging for electronic products, plastic packaging for food, plastic packaging for cosmetics, plastic packaging for computer peripherals, plastic packaging for toys Packaging, sporting goods blister packaging, stationery blister packaging, etc. Its main structure is composed of a feeding, pulling, upper and lower electric heating furnace, lower gate, multi-function adjustable size, lower die plate, upper die, upper gate, knife gate, slicing, unwinding, and vacuum device; The pneumatic device is the main power source, and the pulling and feeding of the piece are made of electric, reducer, time relay, intermediate relay, travel switch and other electrical appliances to form a fully automatic control system. The requirements for the control system of the plastic cup forming machine are to ensure easy operation, high precision of mechanical action and temperature control, short production time, and to save the power consumption of the machine as much as possible under the same production conditions.

Vacuum Blister Machine Features

- With a vertical pull tab design, the pull tab is fast, uniform, and stable, and the time occupied by the pull tab is shortened.

- Independent group temperature control: It is assembled with a special dense flat far-infrared ceramic hair piece, and the temperature is uniform.

- Equipped with full-time vibration demoulding, the products produced are not easily deformed and demoulding is easy.

- Molds of different shapes and sizes can be replaced to produce many different blister products.

- The electric heating furnace adopts closed heating to make heating more uniform and reduce heat loss.

- The double-row chain drives the sheet to rotate, ensuring the machine runs at high speed, accurately, and is stable.

- The whole set adopts all imported electrical appliances and pneumatic originals from international famous factories, with stable quality, safety, and durability.

Other Food Container Maker Recommendations

YG provides not only plastic thermoforming machines but also other food container making machines. Such as paper cup machines, paper bowl machine, rectangular paper bowl machines, plastic cover making machine, paper lid forming machines, aluminum foil lunch box making machine, PS foam food box machine, and other equipment.

-

1. Express plastic bag material: low density polyethylene (LDPE) usually refers to PE, high density polyethylene (HDPE) usually refers to PO, express plastic bags made by the courier bag making machine have the advantages of low cost and light weight.

Food bag manufacturers tell you the difference between PE and PO in express plastic bags: PE has better transparency, softness and brighter printing color; PO has relatively good mechanical properties; domestic express packaging bags are also made of PE As the main material, foreign express uses PE and PO compound as the main express material.

Food bag manufacturers tell you that there are two types of polyethylene express bags on the market: one is new material express bags, and the other is recycled material express bags

2. The cover material of the messenger document: white paper with gray background, white cardboard and kraft cardboard are the majority. Compared with express plastic bags, express document seals have the advantage of being flat and not easily broken.

3. Express bubble bag material: a transparent flexible packaging bag filled with the atmosphere by the air cushion film layer in the middle. It is mainly used for the packaging of small, fragile, fragile and less detailed goods in the express industry. The Quick Bubble Bag comes with shock absorbing bubble wrap. There are some small air bubbles in the bubble film, so it is light and soft, with good shock absorption, impact resistance, non-toxic, odorless, moisture-proof and corrosion-resistant properties.

4. Fast bone bag material: Food bag manufacturers tell you that bone bag (also called compact bag, made of any bag, seal bag, zipper bag, ziplock bag, polyethylene (LDPE) and low pressure linear polyethylene (LLDPE) , made by blown film forming, heat cutting machine) bags, made of resealable plastic bags, bone bags can be used for inner and outer packaging of various small items, self-sealing bags of food materials can store various small foods, Tea, seafood, etc., moisture-proof, waterproof, insect-proof, and avoid equipment scattering.

5. Express woven bag: also known as snakeskin bag. It is a type of plastic used for packaging, and its material is usually various chemical plastics such as polyethylene and polypropylene. The color of the woven bag is usually red or gray-red, non-toxic and tasteless, and it is usually less harmful to the human body. Although it is made of various chemical plastics, it is more environmentally friendly and has a higher acceptance; it is used in packaging and packaging of various items and is widely used in industry.

YG plastic bag making machine manufacturer supply various kinds of plastic bag processing machines.Such as T-shirt bag making machine,zip lock bag making machine,side seal bag making machine,diaper bag making machine,Bag On Roll Machine,flower sleeve bag making machine,ect.

-

The aluminum foil food container making machine is to make aluminum disposable lunch boxes. This series of WB-45T aluminum foil lunch box machine, aluminum foil lunch box equipment, aluminum foil lunch box production line adopts electronically controlled stepping system (PLC electronic control system can be used according to customer requirements), has the function of forward and reverse rotation of the host, and adopts Japanese double safety electromagnetic Valves, pressure switches ensure safe operation. The open-type fixed table high-quality air pressure punch adopts steel plate welded body with high rigidity. It is characterized by the use of dry friction clutch, which can make the slider stop at any position urgently, and at the same time can realize single, inching and continuous operation, which is beneficial to adjust the position of the mold and the workpiece at any time and improve the processing accuracy. The whole machine adopts imported PLC centralized control, and is equipped with safety double valve and balance cylinder, which works stably and reliably. It can be equipped with a light curtain protection device, which is a safety press. The transmission system is enclosed inside the fuselage and has a compact structure. The production line adopts an independent mobile operation station, with eye-catching colors, centralized and convenient operation, and beautiful appearance.The production process of aluminum foil lunch boxes is roughly divided into six steps: exhibition → oiling → feeding → blanking → stamping and forming → testing. During the production process, the stamping force of the aluminum foil is as high as 40-80 tons, and the stamping frequency is 1-2 seconds.The production process of the aluminum foil lunch box is to put the raw material of the aluminum foil on the production line and follow the crawler to the stamping machine, which is a powerful stamping... The pattern is directly made on the mold, and the aluminum foil is made by pressing up and down. The look of a snack box. The punched lunch boxes will be brought to the assembly line by the airflow and then collected by workers for sterilization and packing.In addition, Yugong also provides paper bowl making machine, square paper bowl machine, paper bowl lid making machine, plastic lid forming machine and other food container maker.

-

The PS foam food box machine is used to process the foamed coil and make the foamed coil into various shapes of food containers. According to different molds, it can make various foaming containers such as foamed dishes, foamed lunch boxes, foamed trays and so on. And foam sheet unit, vacuum forming machine, plastic pulverizer, plastic recycling line, etc. can also form a foam lunch box production line.

-

-

With the introduction of plastic restriction orders and plastic ban orders in various countries, the market of the paper products industry has further expanded. The use of paper instead of plastic has been reflected in many industry scenarios such as catering, takeaway, and express delivery.

Overview of Paper Products

From the perspective of the industrial chain, the upstream of the paper product industry includes the paper processing industry, for example, the processing industry of various paper products such as paper, cardboard, handmade paper, and processed paper.

The downstream industry of paper products is mainly the processing industry of various paper products. For example, toilet paper processing industry, copy paper processing industry, catering paper product processing, signage and other paper product processing industries.

Development Status of Paper Products Industry

In recent years, my country's paper product packaging industry has maintained a steady development trend. The number of companies entering the paper product processing industry has continued to grow, and the industry's revenue scale and profit have maintained steady growth. According to statistics, in 2020, the enterprises above designated size in my country's paper product packaging industry realized the main business income of 288.474 billion yuan, a year-on-year decrease of 0.43%; A year-on-year increase of 23.05%.

In recent years, my country's export of paper products and paper product processing equipment to foreign countries is also increasing. As the global packaging industry gradually shifts to developing countries and regions represented by China, the export status of my country's paper product packaging industry has become increasingly prominent. In 2020, the total import and export volume of my country's paper packaging industry was 6.76 billion US dollars, of which the export value was 6.613 billion US dollars, a year-on-year increase of 4.08%.

The future development trend of paper products industry

Green environmental protection and economic development are the common goals pursued by all countries. Green environmental protection is to achieve green environmental protection from design, production, packaging and other links. In the future, the paper product development industry will surely develop towards recyclability, reuse, degradability, de-plasticization and replacement of plastic.

Production intelligence, automation

With the improvement of scientific and technological water bottles, the production of the packaging industry will gradually develop towards automation and intelligence in the future. Intelligent production, integrated printing and packaging, digital manufacturing, etc. not only greatly improve production efficiency, release labor, and reduce labor costs. And it will also create greater economic benefits.

Production service capability upgrade

With the rapid economic and social development, the stickiness of upstream and downstream industries will be further strengthened. The paper products produced by the production industry provide diversified demands for the processing and manufacturing of downstream industries. Paper product manufacturers will also be upgraded to become comprehensive service providers, and the requirements for comprehensive service will be gradually upgraded.

Paper product processing equipment

Paper product processing equipment occupies an important position in the development of the paper product industry. It is the most important equipment to realize the rapid processing of paper products and create economic benefits. The upstream paper product industry includes paper machines, which create various types of base paper and provide raw materials downstream. There are many downstream paper products processing equipment, such as tissue paper making machine, paper core making machine,paper bowl machine, paper cup machine,paper bag machine,diaper manufacturing machine,plastic lid forming machine, paper rewinding machine,rectangular paper bowl making machine, punching machine, slitting machine, copy paper processing equipment and other processing machines.

-

Paper tube making machine for film,food,toilet paper

Toilet paper core making equipment is a machine and equipment for producing paper tubes. The produced paper tubes are used in various industries, such as tubes for chemical fiber industry, tubes for film industry, tubes for printing industry, tubes for paper industry, and tubes for leather industry. Tubes, food packaging tubes, construction industry tubes, exhibition industry tubes, etc. There are also various types of paper tube machines. The most common paper tube machine is the spiral paper tube machine and the flat roll paper tube machine.

1. Suitable for high-strength paper tubes such as aluminum foil, steel strip, copper foil, construction industry, etc.

2. The electrical appliance adopts the Japanese Mitsubishi brand.

3. There is a single-knife hydraulic knife/electric saw.

4. The main machine of the paper tube machine has a swing function, which does not need to move the glue rack and the paper rack. The operation is simple and convenient, saving labor and space, and with frequency conversion to save electricity.

5. High processing precision, using thick materials and precise electrical appliances.

YG supplies a wide variety of paper product processing equipment. For example, toilet paper making machine, paper bag machine, paper cup manufacturing machine, baby adult diaper making machine, sanitary pads making machine,wet wipe machine, paper rewinding machine for sale and other equipment.

-

PLA PBAT Biodegradable Film Blowing Machine

【**Introduction**】Biodegradable film blowing machine is an automatic equipment designed by YG specially for making biodegradable films from biodegradable materials.

【**Contact**】whatsapp/wechat/tel:+86 15037187716

Email: plastic@yugongmachine.com

-

Whether it is a normal plastic bag or a biodegradable plastic bag, their production process is roughly similar.

First, you need to use a blown film extrusion machine to blow the plastic raw material into plastic film. The plastic film is then made into plastic bags using a bag making machine. If you need to print a pattern on a plastic bag, you need to use a printing machine to print the pattern on the plastic film before making the bag.

Compared with the production of ordinary plastic bags, the production of biodegradable plastic bags requires the use of degradable plastic materials to make plastic films. For example, PLA, PBAT, corn starch and other degradable plastic materials.

Since plastics are difficult to degrade naturally, with the introduction of plastic restriction orders in various countries, many plastic processors have turned to the processing of biodegradable plastics. Products processed from biodegradable plastics can be completely decomposed by environmental microorganisms in the natural environment. It can eventually be completely degraded into carbon dioxide, methane, water and other compounds.

YG Plastic Packaging Machine also provides various plastic bags, and plastic bottle making machines. Such as T-shirt bag making machine, courier bag making machine, diaper bag making machine, zipper bag making machine, mineral bottle blowing machine, flower sleeve bag making machine, etc.

-

-

Toilet paper core making equipment is a machine and equipment for producing paper tubes. The produced paper tubes are used in various industries, such as tubes for chemical fiber industry, tubes for film industry, tubes for printing industry, tubes for paper industry, and tubes for leather industry. Tubes, food packaging tubes, construction industry tubes, exhibition industry tubes, etc. There are also various types of paper tube machines. The most common paper tube machine is the spiral paper tube machine and the flat roll paper tube machine.

1. Suitable for high-strength paper tubes such as aluminum foil, steel strip, copper foil, construction industry, etc.

2. The electrical appliance adopts the Japanese Mitsubishi brand.

3. There is a single-knife hydraulic knife/electric saw.

4. The main machine of the paper tube machine has a swing function, which does not need to move the glue rack and the paper rack. The operation is simple and convenient, saving labor and space, and with frequency conversion to save electricity.

5. High processing precision, using thick materials and precise electrical appliances.

YG supplies a wide variety of paper product processing equipment. For example, toilet paper making machine, paper bag machine, paper cup manufacturing machine, baby adult diaper making machine, sanitary pads making machine,wet wipe machine, paper rewinding machine for sale and other equipment.

-

Fog cannon machine, also known as mist cannon machine and water mist cannon spraying machine, is a device specially developed for dust suppression. Now the equipment can be used to print dust in the environment or in places with large dust such as mines, docks, and stone quarries. The sprayed water mist can well condense with the dust, and the dust falls under the action of gravity, and the dust removal and dust suppression effect is remarkable.

Why do you need a fog cannon?

Long-term exposure to dust will cause harm to the human body. Dust may poison the human body, damage the cornea, cause pneumoconiosis, and affect skin health. The water mist sprayed by the fog cannon is the best device to suppress the split. Therefore, many factories, docks, transfer stations, mines, coal yards, etc. that generate a lot of dust will use this equipment for dust suppression.

Fog Cannon Model:

Fog cannon fan material: Q235. Q345 steel plate or 304 stainless steel material,

The thickness of the air duct steel plate is greater than 3mm

Fog cannon electrical control box: carbon steel control box or 304 stainless steel control box, with double door structure, the thickness of the control box is not less than 2mm

Explosion-proof fog cannon electrical control box:

(1) Carbon steel explosion-proof control box

(2) 304 stainless steel explosion-proof control box (overall thickness 4mm, flange thickness 12mm)

Protective function:

(1) Phase sequence protection, the fans, and pumps will not start when the phase sequence is reversed

(2) Overcurrent protection, when the current of the device is too large, the device will automatically stop running

(1) Low water pressure protection, when the water pressure is too low, the equipment will automatically stop running to protect the water pump

(2) Automatic drainage, when the equipment is shut down, the water in the pipeline is automatically drained

Heating: use self-limiting heat tracing cables to prevent ice from freezing on the spray ring and the water pump to meet the requirements of winter use

Nozzle selection: copper nozzle, high quality 304 stainless steel nozzle

Conditions for suppressing dust

Dust suppression requires two conditions:

1. There are enough dust particles and water droplets of the same size.

2. Dust particles and water droplets are in a closed area so that the agglomeration can fully occur and continue.

The high-pressure spray fan produced by Zhengtong can generate ultra-fine mist droplets through the strong wind formed by system pressurization and turbocharging. The weather can spray dust, decompose and desalinate the particle concentration in the air, and can effectively decompose the polluting particles and dust in the air, and effectively relieve the haze. According to reports, the purchase of such a big guy costs 50,000 to 150,000 yuan. The pollutant particles floating in the air are quickly forced to the ground to achieve the effect of cleaning the dust-reducing air.

Advantages compared to ordinary sprinklers:

The fog cannon can be directly installed at the rear of the sprinkler and can be atomized into beads equivalent to the dust by pressure. The energy is completely suppressed, and at the same time, the amount can be adjusted according to actual needs. Compared with the ordinary sprinkler, it can save 50%, and the resource rate is improved. The ordinary sprinkler only sprays along the nozzle to suppress the road dust, and cannot effectively and quickly solve the dust in the air.

Related machines

YG machine manufacturer also supplies the environmental machine (fog cannon machine, slope hydroseeding machine), sanitary equipment(paper rewinding machine, toilet paper making machine, nonwoven bag making machine), construction machine(Diamond Wire Saw Machine, concrete wall saw, rock splitter machine), wire mesh welding machine and other machines.

-

Wedding, Banquet Foil Balloon Making Machine

To create a romantic, happy atmosphere, balloons are usually used for decoration. For example, balloons are used for decoration at weddings, birthday parties, business banquets and other high-end places. According to the material of producing balloons, there are mainly aluminum foil balloons and latex balloons. Can you tell the difference between the two types of balloons? Do you know how aluminum foil balloons are made?

Foil Balloons

Aluminum foil balloons are also called aluminum film balloons, which are made of aluminum film materials. Since the balloons are printed, they come in a variety of patterns and colors. The aluminum film balloon has an air nozzle that can be inflated, and it lasts for a long time after inflation. The aluminum foil balloon itself will not be damaged without external force.

latex balloon

Latex balloons are made of 100% natural rubber, no other artificial rubber is added, so latex balloons can be naturally decomposed. In terms of color, latex balloons have four categories: standard color, pearlescent color, crystal color, and fluorescent color. Shapes include circle, heart, plum blossom, magic strip, etc.

How to Make Foil Balloons?

Latex balloons and foil balloons are made using different balloon making machines. Here's how to make an aluminum foil balloon. Aluminum foil balloons are generally available with printed patterns and without patterns. The aluminum foil raw material is prevented from being placed on the reel, and it is made by cutting the aluminum foil balloon making machine, filling the air nozzle, and printing the pattern. From the raw material to the final product, it is automatically completed by the aluminum foil balloon making machine. Using the automatic aluminum foil balloon making machine to make aluminum foil balloons has high production efficiency and regular production shapes.

Yugong construction machinery equipment manufacturers also provide construction-specific machinery, such as Scrap Metal Shear For Excavator, paper rewinding machine, gunite machine for sale, slope hydroseeding machine, automatic sandblasting machine, ect.

-

What is wet sandblasting?

Wet blasting is a technique for surface preparation using water, abrasives and compressed air.

"Wet blasting" refers to a technology that uses the power of compressed air to spray a mixture of water and abrasives at high speed to achieve surface cleaning, processing and modification of metals, plastics, ceramics and other materials. Since it is wet processing, it is also suitable for fine processing using abrasives as small as several microns.

Advantages of wet blasting

Wide selection of abrasive grain sizes, shapes and materials

Because the abrasive particles are carried by water to the target, finer particles can be used compared to dry blasting.High fluid control and controllability

The grinding fluid mixed with water and abrasive grains can realize fluid control, so the processing precision is higher.Less abrasive residue

After machining, the abrasive particles are washed away by water, so less particles remain on the machined surface.Capable of handling ultra-thin targets

The processing pressure is small, and the ultra-thin target will not be damaged during processing.Adding chemicals can get the effect of secondary treatment

Chemicals can be dissolved in water, and chemical treatment can be performed at the same time as sandblasting.The principle of wet sandblasting

Wet sandblasting is an easy-to-automate and environmentally friendly way to circulate the grinding fluid.

The basic principle of wet sandblasting is as follows. The grinding liquid (mixture of water and abrasive) in the grinding liquid tank is drawn to the sandblasting gun by a pump, and is sprayed onto the target material by the action of compressed air in the sandblasting gun. The grinding fluid is recovered to the grinding fluid tank for recycling. Click here to know more wet blasting machine details. -

“Minimally Invasive Operation”for laying urban pipe network -- the brief introduction of HDD Horizontal Directional Drilling Equipment

We often find that in the city where we live, roads are often dug up. Whether newly built or used for a period of time, we always feel that the roads around our residence have never been intact. We dig and repair them every day, it is not convenient to travel, but also causes environmental pollution, the phenomenon of digging out a part of the road is also known as the “Zipper link.”.

The main reason for this type of Zipper is not only that the road is damaged, but also that the road was not well planned when it was built, and with the rapid development of the city, the existing underground pipelines can not keep up with the demand of the city, in addition, some new pipelines also need to cross the road.

A few days ago, I saw a news report that a certain place has stipulated that the newly-built urban roads should not be dug up for 5 years after they are delivered for use. This will effectively put an end to the phenomenon that urban roads are often dug up. It will also avoid the economic losses caused by the repeated occurrence of “Zipper links”.

But at the same time, it puts forward higher requests to the construction of the underground pipe network of the city road.

Do you often see a machine at work in the city’s green belt, or on the sidewalk, inserting a rotating iron pipe into the ground to make a hole, and not far away inserting cables and pipes into the hole made by the machine, this machine is the HDD drilling machine.

A horizontal Directional Drilling Machine is the mechanical equipment for laying underground pipelines without the need to excavate the ground. It can avoid obstacles successfully within a certain radius of the ground. It can be operated in underground strata such as clay, sand, and so on. It is widely used in electric power, flexible pipeline laying in the fields of communications, oil, and natural gas.

Unlike road closures and major road repairs, horizontal directional drilling rigs can be built on the side of the road without affecting traffic or people’s normal travel, as we often see.

Through the advanced equipment calculation and positioning, can let the whole drill through the process of bypassing obstacles to reach the intended location, to ensure the construction accuracy.

Compared with the traditional construction method, horizontal directional drilling has many advantages such as high construction efficiency, low cost, no environmental impact and so on.

-

These pages are also talking about HDD drilling rigs. Please click here to know more horizontal directional drilling machines.

-

-

Concrete Gunite Machine Application

Concrete sprayers are widely used in tunnels, culverts, foundation pits, tunnels, subways, bridges, coal mines, swamp mines, hydropower projects, underground projects, construction projects, dams, slopes, dangerous rocks, and other basic engineering protection projects. It is used for shotcrete construction operations to prevent sand and gravel from falling on dangerous rocks and debris such as tunnel walls and slopes, and to prevent landslides.

Shotcrete Machine Classification

According to the different ways of adding water to the concrete mixture, it can be divided into three types: dry shotcrete machine, wet shotcrete machine, and semi-wet shotcrete machine in between.

According to the structure principle of the shotcrete machine, it can be divided into four types: cylinder type, screw type, rotor type, and hydraulic type.

According to the number of nozzles, it can be divided into single shotcrete machine, double shotcrete machine, and three shotcrete shotcrete shotcrete machines.

According to the degree of automation, it is divided into ordinary concrete shotcrete machine and concrete wet spraying manipulator (intelligent wet spraying trolley)-

YG machinery specializes in producing all kinds of construction machinery, slope tunnel support equipment. For example concrete gunite machine(shotcrete machine), shotcrete truck. Mortar spraying machine(cement spraying machine), mobile concrete pump, small concrete pump, mini concrete pump. Shot blasting machine, sandblasting machine,

-

-

Development of HDD Drilling Machine

Horizontal Directional drilling is a new construction method that combines the common pipeline laying technology with the drilling technology used in oil exploitation.

When the horizontal directional drilling machine was not invented, it was not only inefficient but also costly to dig holes and sink pipes when laying pipelines to cross rivers or obstacles.

Horizontal Directional drilling first appeared in the United States, in the 1960s, an American engineer used oil field directional drilling technology in the pipeline.

Later, reaming technology was invented, which also made it possible to lay large diameter pipes, and a new horizontal directional drilling technology was formed.

China first introduced this horizontal directional drilling technology in the 1980s. With the rapid construction of crude oil pipelines and urban pipelines in recent decades, horizontal directional drilling has developed rapidly in China, both the length of the crossing and the diameter of the pipeline have set many records.

We all know that it takes a lot of skill to extract oil, and that’s because it’s buried in the ground where you can’t see it, and it takes a lot of hard work to extract it.

In the exploitation of the first need to carry out very important drilling work, but also according to different geological and use different methods to drill wells, so as to obtain oil resources.

The traditional method of drilling wells is usually vertical drilling, but in many cases, horizontal drilling in the ground is used to find oil. This technique uses advanced acoustic and Gamma-Ray functions on the drill bit, when drilling, the data in the formation is collected by the bit and transmitted to the ground operator, so that a more ideal drilling plan can be adopted in real-time, and the bit can be controlled to bend forward in the ground at will, that would be like installing a clairvoyant on an underground drill that would eventually find oil.

Since the appearance of the YG HDD drilling technology, the human drilling technology has improved a step, improved the production efficiency and reduced the engineering risk.

With the requirement of energy-saving and environmental protection getting higher and higher, horizontal directional drilling rig, a kind of trenchless pipeline laying equipment, will be used more and more widely.